3 Axis Vertical Machining Center VMC650 is a vertical bed structure, the feed axis is X, Y, Z three coordinate control, the main shaft is servo motor power drive, CNC Machining Center Manufacturers VMC650 the power is 5.5Kw, the maximum speed is 8000rpm; the double nut preload C3 ball Lead screw, machine positioning accuracy is ±0.01mm; optional tool magazine, accurate and reliable tool change; machine tool numerical control operating system has customer choice, machine tool can realize complex parts of various discs, plates, shells, cams, molds, etc. 3 Axis Vertical Machining Center VMC650 is suitable for high-efficiency and high-precision automatic processing of small and medium-sized parts in the fields of teaching, aerospace, military and national defense, automobile and motorcycle, engineering machinery, refrigeration and petrochemical, and rolling stock.

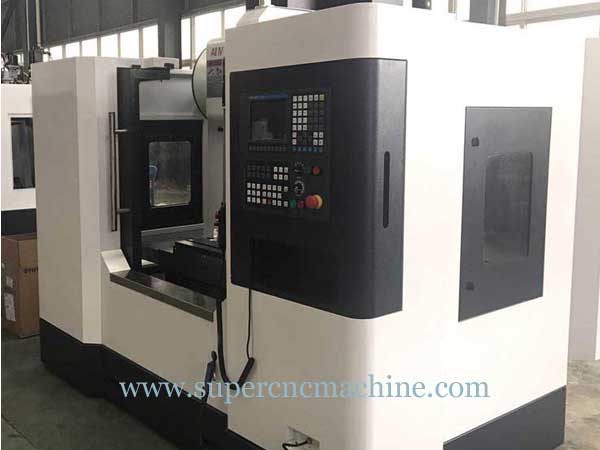

3 Axis Vertical Machining Center VMC650

Description

3 Axis Vertical Machining Center VMC650 engineered with the vertical bed structure and three feed axises, its main shaft is servo motor drive. 3 Axis Vertical Machining Center VMC650 the power is 5.5Kw, and its maximum speed is 8000rpm; 3 Axis Vertical Machining Center is equipped with double nut preload C3 ball Lead screw, its machining positioning accuracy is ±0.01mm. This tool magazine is optional with accurate and reliable tool change. Our 3 Axis Vertical Machining Center VMC650can realize complex parts of various discs, plates, shells, cams, molds, etc. One-time clamping, complete drilling, milling, boring, expanding, reaming, tapping and other processes, it is suitable for the production of multi-variety, small and medium-sized products, showing the superiority of processing complex and high-precision parts. 3 Axis Vertical Machining Center VMC650 is suitable for high-efficiency and high-precision automatic processing of small and medium-sized parts in the fields of teaching, aerospace, military and national defense, automobile and motorcycle, engineering machinery, refrigeration and petrochemical, and rolling stock.

3 Axis Vertical Machining Center VMC650 parameter

| No | Item | VMC650 |

|---|---|---|

| 1 | X-axis travel | 650mm |

| 2 | Y-axis travel | 400mm |

| 3 | Z-axis travel | 500 mm |

| 4 | Spindle nose to table | 70-570mm |

| 6 | Workbench size | 800×400 mm |

| 7 | T-slot | 16×3×80 mm |

| 8 | Workbench maximum load | 500kg |

| 9 | Spindle taper | BT40 |

| 10 | Spindle power | 5.5kw |

| 11 | Spindle rotation number | 8000rpm |

| 12 | Cutting speed | 1-6000 mm/min |

| 13 | Fast speed | X/Y/Z: 20m/min |

| 14 | Positioning accuracy | ±0.01/300 mm |

| 17 | Machine tool footprint | 2600×2300×2500 mm |

| 18 | Machine weight | 3600kg |

3 Axis Vertical Machining Center VMC650 features

★High rigidity: It adopts the bed-type machining center structure. CNC machining center is composed of base, sliding seat, work table, column, and headstock. The main basic parts are analyzed by finite element structure, the structure is reasonable and the rigidity is large; all machine tool castings are Thermal aging treatment, precision has long-term stability.

★CNC milling machine tool adopts high-speed, high-precision and high-rigidity spindle unit. 3 Axis Vertical Machining Center VMC650 spindle material is made of high-performance alloy steel. The high-speed precision bearing for the spindle is used, and high-speed grease is used. The spindle speed reaches 8000 rpm and the spindle radial runout is less than 0.008/300.

★X, Y, Z direction feed adopts C3 grade double nut preloaded precision ball screw. The servo motor is directly connected with the lead screw through high torque and low inertia imported elastic coupling to ensure positioning accuracy and repeat positioning accuracy.

Power and environmental requirements

1.Power supply and environmental requirements

1.1 Power supply voltage: 380V ± 10%

1.2 Power frequency: 50HZ ± 1%, three-phase

1.3 Gas source: 6kg/cm2 After proper drying

2.Environmental conditions for use

2.1 Relative humidity: ≤80%

2.2Ambient temperature: 0°C-40°C

2.3Air medium: non-corrosive medium

2.4 Light: adequate, well ventilated

2.5CNC machine for sale works stable for a long time under the above working conditions.

3.Installation site conditions

3.1Not affected by external vibration.

3.2Not affected by corrosive gases.

3.3Avoid direct sunlight on a machining center.

3.4Avoid direct contact with outside wind, air and temperature regulation of cold and hot air.

3.5Avoid setting heat sources such as heating near vertical machining center.

3.6Reduce dust (avoid castings, welding, sheet metal workshops, etc.).

3.7Avoid water leakage and water immersion.

3.8Avoid electrical noise.

About HAISHU Machinery

As the professional CNC machine designer and manufacturer, Taian HAISHU Machinery Co., Ltd (Haishu Machinery) is the high-tech enterprise specialized in CNC machine development, production, sales and service since 2001. We have more than 30 professional talented CNC experts and more than 12,000 square meters manufacturing factory. Our high quality and innovative products include CNC lathe, CNC milling machine, CNC machining center, CNC turn-mill machine, CNC tool grinding machine, CNC pipe threading lathe, CNC wood lathe, stone CNC machine, CNC root canal file grinder and custom CNC equipment for special requirements.

HAISHU Machinery is not only manufacturing best quality CNC machine products but also providing custom product design and after sale services. Welcome, contact us for detailed information.