Description

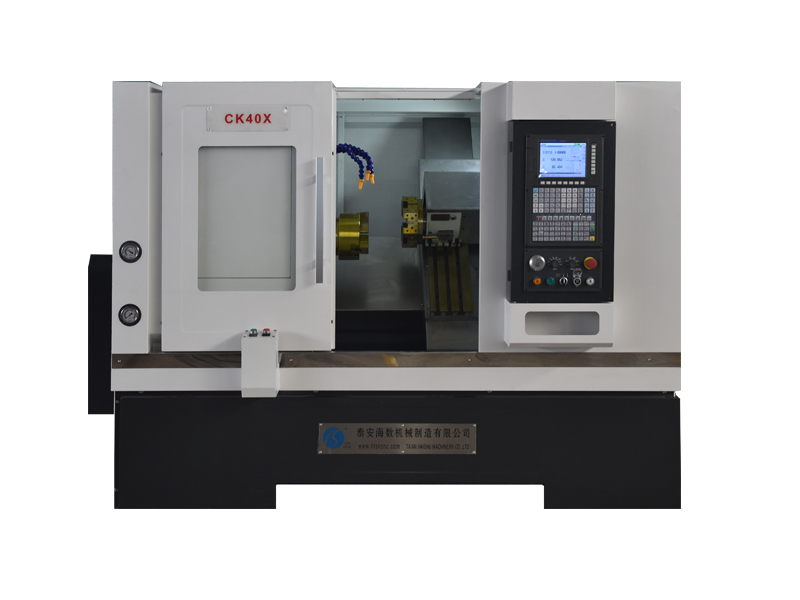

CX40X slant bed CNC lathe is an affordable option featuring a compact, powerful slant-bed CNC lathe that operates on single-phase power. CX40X slant bed CNC lathe is specially designed for metal piece machining in the automotive industry, mechanical engineering or medical technology, among others.

HAISHU Machinery is the professional CNC lathe manufacturer and supplier, we offer a wide range of custom CNC lathe with wide specifications at best factory price.

1.What Is Slant Bed CNC Lathe?

A slant bed CNC lathe is a type of computer numerical control (CNC) lathe machine that features a bed or base inclined at an angle instead of being horizontal. This design offers several advantages over traditional horizontal bed lathes.

The slanted bed allows chips and debris to fall more freely during the machining process, improving chip flow and reducing the likelihood of chip accumulation. This helps maintain better machining accuracy and reduces the need for frequent cleaning or interruptions.

Additionally, the slant bed design enables larger X-axis travels, providing increased machine flexibility and capacity. This allows for the machining of larger and more complex parts.

The use of a slant bed CNC lathe can result in enhanced productivity, reduced machining costs, and improved part quality. The improved chip control and larger part size capabilities contribute to faster and more efficient machining operations. This, in turn, leads to cost savings and higher-quality finished parts.

The slant bed CNC lathe offers numerous advantages in terms of chip flow, part size capacity, productivity, cost-effectiveness, and part quality, making it a preferred choice for many machining and manufacturing applications.

2. Technical Data Of CX40X Slant Bed CNC Lathe

| 1 |

Item |

|

Unit |

Tchnical Data |

| 2 |

Processing Capacity |

Maximum workpiece rotation diameter on the bed |

mm |

400 |

| Maximum workpiece rotation diameter on the slide |

mm |

180 |

| Maximum workpiece turning diameter (disc type) |

mm |

300 |

| Processing length |

mm |

200 |

| Maximum bar diameter |

mm |

Ф41 |

| 3 |

Spindle |

Spindle through hole diameter |

mm |

Ф49 |

| Spindle head form |

|

A2-5 |

| Spindle maximum speed |

r/min |

2800 |

| Clamping form |

|

Hydraulic/pneumatic/manual |

| 4 |

Knife holder |

Tool holder form |

|

Inline tool holder/electric tool holder/tool turret |

| Knife specifications |

mm |

20*20 |

| Maximum sharp tool shank diameter |

mm |

25 |

| 5 |

Feed |

X/Z direction screw |

Jiangsu Wanrun |

X:3210/Z:3210 |

| X/Z guide rail |

Jiaxing Meisen(Optional) Taiwan Bank of China |

35/30 Ball guide |

| X/Z axis |

X-axis/Z-axis maximum travel |

mm |

X:350(Optional 450)/Z:450 |

| X-axis/Z-axis rapid movement speed |

mm/min |

X:20/Z:20 |

| 6 |

Motor |

Spindle motor power |

KW |

3.7/5.5/7.5(optional) |

| X-axis/Z-axis drive motor torque |

Nm |

6/6(optional) |

| Cooling water pump power |

W |

90 |

| 7 |

Weight |

Net weight (approx.) |

kg |

1600 |

| 8 |

Size |

Machine tool dimensions (length x width x height) |

mm |

2150*1500*1650 |

3. What Is CX40X Slant Bed CNC Lathe?

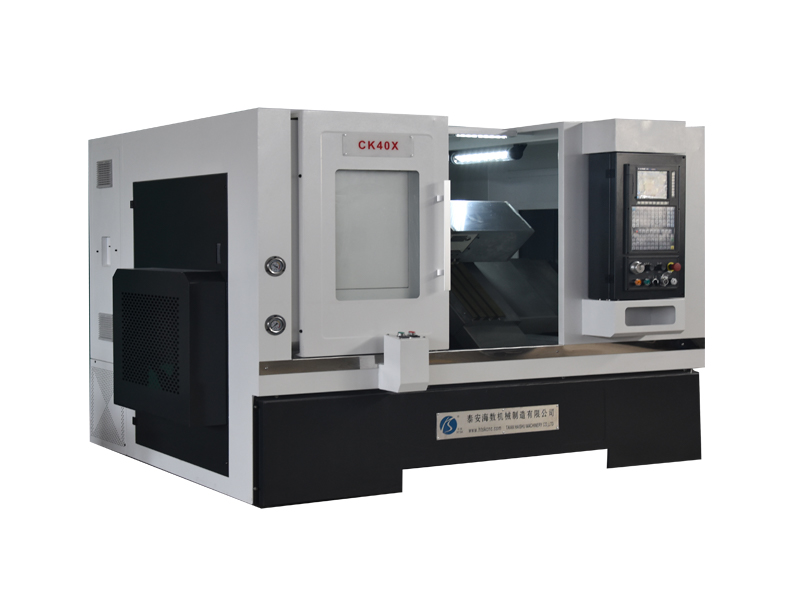

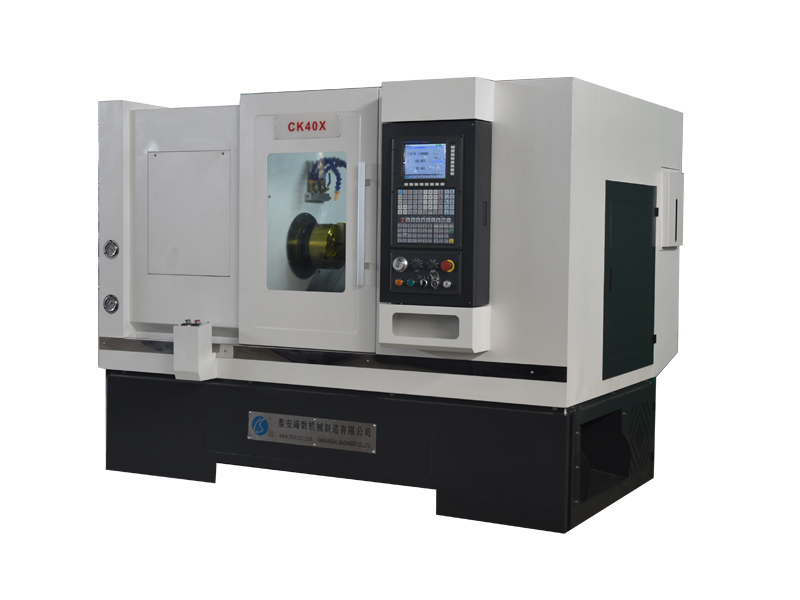

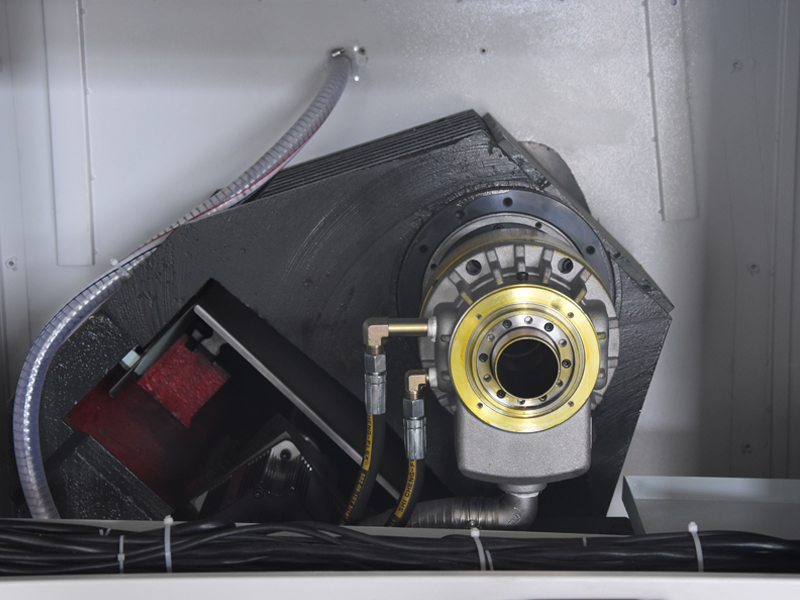

The CX40X slant bed CNC lathe, designed and manufactured by HAISHU Machinery, is a horizontal turning center featuring a 45° slant bed. With its widened 30° flat rail, this CNC lathe offers a turning capacity of 400mm in diameter and can accommodate parts up to 200mm in length. It boasts a one-piece casting construction, providing superior rigidity and effective vibration dampening.

The compact design of the CX40X slant bed lathe is optimized for efficient chip removal and offers high stiffness and precision. It is particularly well-suited for reliable and efficient turning in series production. The machine is equipped with a powerful drive and a stable fast tool changer, ensuring economical production processes.

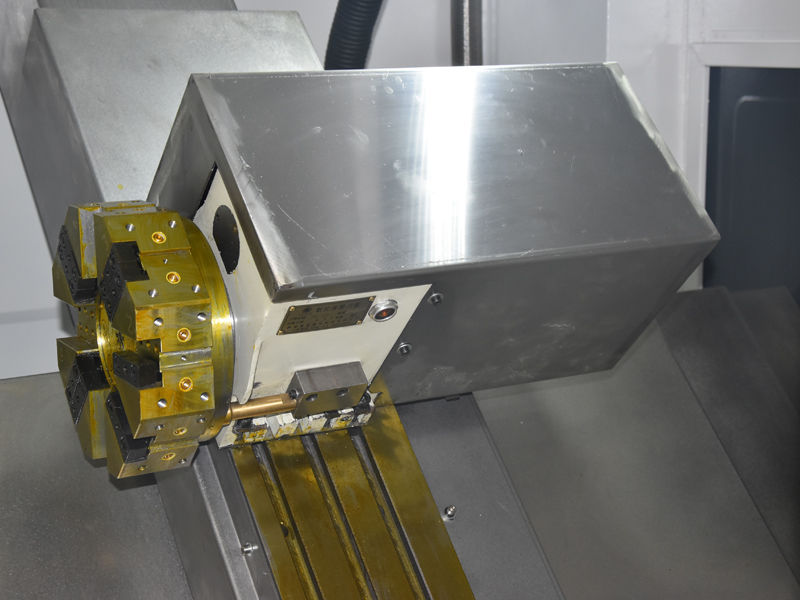

The CX40X slant bed CNC lathe is equipped with the advanced GSK980tdi CNC system, enabling support for complex macro programs such as Class A and Class B macros. It features an absolute value configuration with a power-off memory coordinate function, allowing processing to resume from any position after power-on. The straight-line tool holder enhances rigidity and reduces tool change time, eliminating potential failure points. This enables quick tool changes during processing. The guide rail utilizes a linear guide rail system, available in both ball and roller structures to meet the processing requirements of different workpieces, especially for arc workpiece processing. The chuck is a hydraulic hollow power chuck, facilitating batch and automated processing.

Overall, the CX40X slant bed CNC lathe offers a combination of advanced features and capabilities. Its slant bed design, widened flat rail, rigid construction, and efficient chip removal ensure optimal performance and precision. With the GSK980tdi CNC system, it supports complex programming and delivers reliable and economical production processes. Whether for small batch or high-volume production, the CX40X slant bed CNC lathe is a versatile and efficient solution for a wide range of turning applications.

4. What Are The Advantages of CX40X Slant Bed CNC Lathe?

The CX40X slant bed lathe offers several advantages over traditional horizontal bed lathes, including:

4.1 Superior Chip Removal Performance

The slanted design of the bed allows chips and debris to fall more freely during the machining process. This improves chip flow and reduces the likelihood of chip accumulation, leading to better machining accuracy and efficiency.

4.2 Extended Machine Life

The slanted bed design helps to minimize undue stress and wear on the guides and other components of the lathe. This can result in a longer machine life and reduced maintenance requirements.

4.3 Larger X-axis Travels

The slant bed design allows for larger X-axis travels compared to horizontal bed lathes. This increased travel capability provides greater flexibility and the ability to machine larger workpieces.

4.4 Larger Part Capacity

The slant bed lathe can accommodate larger parts due to its design. The inclined bed allows for increased clearance and space for larger workpieces to be mounted and machined.

These advantages contribute to the overall performance and efficiency of the slant bed lathe. They enhance chip control, reduce maintenance needs, increase machine flexibility, and allow for the machining of larger and more complex parts. As a result, slant bed lathes are widely used in various industries where improved chip removal, extended machine life, and larger part capacity are desired.

5. What Are CX40X Slant Bed CNC Lathe Used For?

The CX40X CNC slant bed lathe, featuring a straight-line tool holder, is highly suitable for processing small and precision workpieces. It finds primary application in automobile manufacturing and the production of small automobile parts, such as metal plugs. It is also commonly used in the aerospace field for aviation plugs, as well as in medical equipment, mold manufacturing, the electronics industry, optical equipment, and metal processing. The versatility of the CX40X lathe makes it a valuable tool in various industries requiring precise and efficient machining of small components.

6. About HAISHU Machinery

As the professional CNC machine designer and manufacturer, Taian HAISHU Machinery Co., Ltd (Haishu Machinery) is the high-tech enterprise specialized in CNC machine development, production, sales and service since 2001. We have more than 30 professional talented CNC experts and more than 12,000 square meters manufacturing factory. Our high quality and innovative products include CNC lathe, CNC milling machine, CNC machining center, CNC turn-mill machine, CNC tool grinding machine, CNC pipe threading lathe, CNC wood lathe, stone CNC machine, CNC root canal file grinder and custom CNC equipment for special requirements.

HAISHU Machinery is not only manufacturing best quality CNC machine products but also providing custom product design and after sale services. Welcome, contact us for detailed information.