- High efficiency: short machining cycle, reducing non-cutting time; (the second spindle can realize complete synchronous turning, and can quickly transfer workpieces during the machining process through program control, so as to shorten the cycle time).

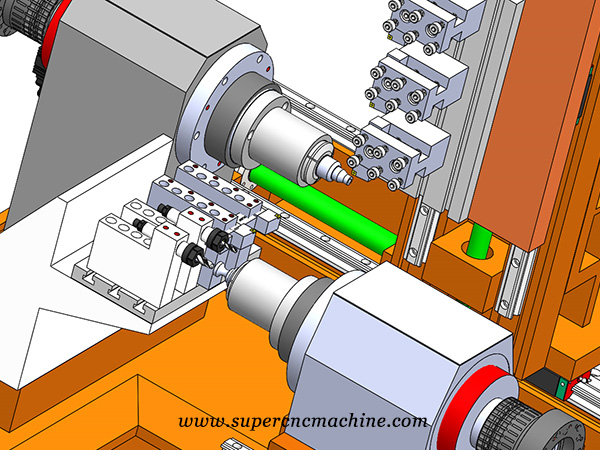

- High precision: Equipped with the second spindle and the second tool post to realize the rotating docking of the workpiece and secondary processing, which reduces the clamping time and improves the coaxiality of the machine tool;

- High space efficiency: the smaller space plays the biggest role, which is convenient for personnel operation and automatic loading and unloading;

- X/Z axis adopts three-point positioning ball screw, which is easy to install, improves the service life of the bearing, reduces the thermal error of the machine tool, has high positioning accuracy, good stability and easy maintenance;

- X/Z axis adopts linear guide rail design, which increases the higher dynamic and static load of the guide rail, improves the rigidity of the machine tool, has high positioning accuracy, good stability and easy maintenance;

- The spindle unit or electric spindle can be customized to ensure that the machine tool has better rigidity during fast operation;

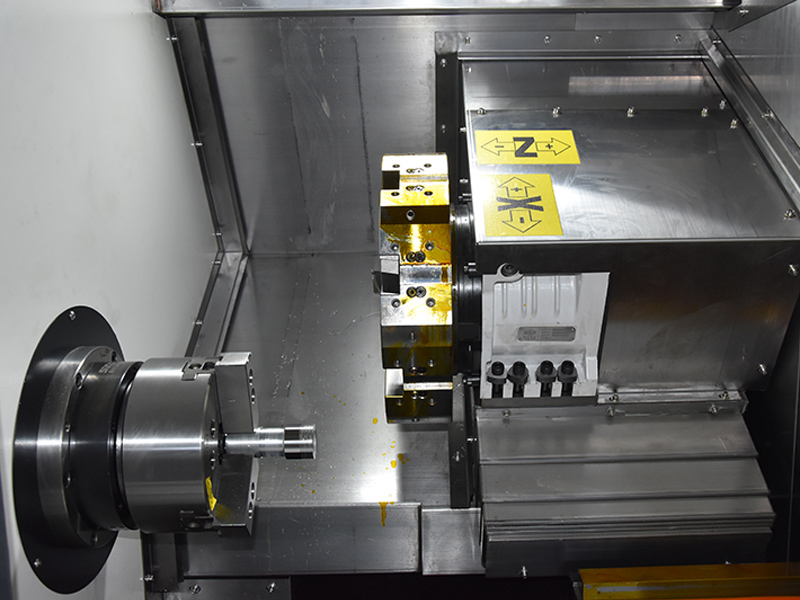

- The machine tool adopts an integral casting bed with good stability. The bed can be clamped and processed at one time, with high precision and durability.

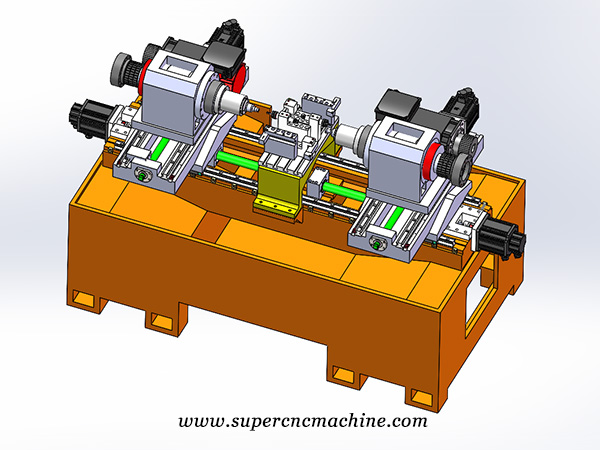

Fully Automatic Double Spindle CNC Lathe Series

Description

Fully automatic double spindle CNC lathe series are the multi functional CNC lathe newly designed and manufactured by HAISHU Machinery. This series CNC lathe machine includes CK35S1 and CK45S1 dual-spindle flat rail CNC lathe, CNC36S1 dual-spindle dual-inclined rail CNC lathe, CNC36S1 dual-spindle dual-inclined rail CNC lathe. This double spindle CNC lathe series of machine tools adopts an integrated structure of mechanical, electrical, and hydraulic (pneumatic), it can be equipped with automatic feeding mechanism. The overall layout is compact and reasonable. The key outsourcing parts are selected from the standard series of well-known international manufacturers to ensure the accuracy and reliability of the machine tool and achieve the best performance of the whole CNC machine. Therefore, this series of machine tools is particularly suitable for the automotive industry, motorcycle industry, electronics, light industrial machinery and other industries to achieve efficient, high-volume, high-precision automated processing of rotating metal parts.

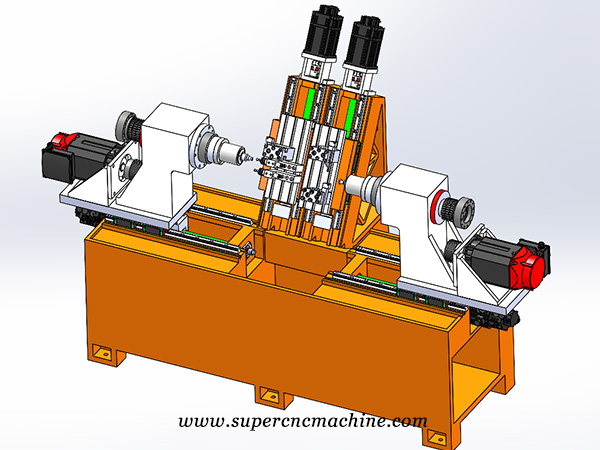

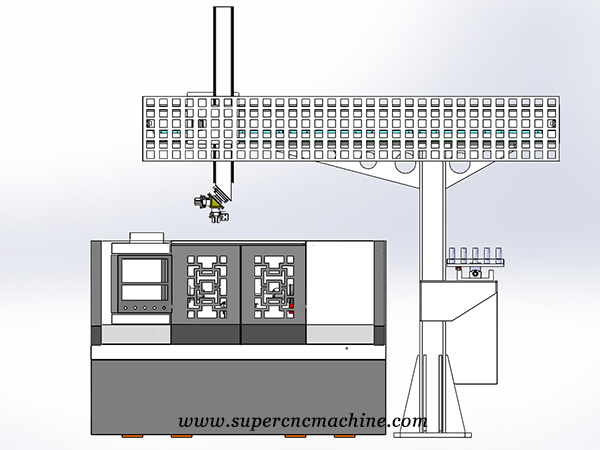

- CK35S1 and CK45S1 CNC Lathe With Truss Feeding Mechanism

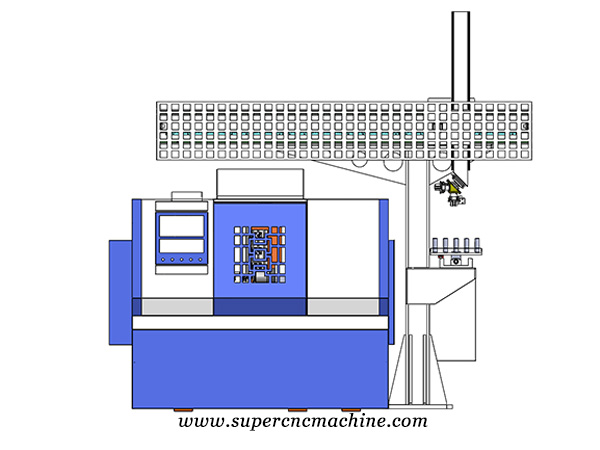

- CK42S2 CNC Lathe With Truss Feeding Mechanism

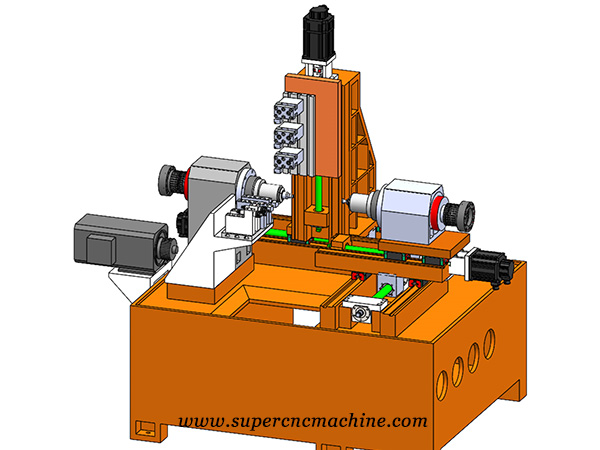

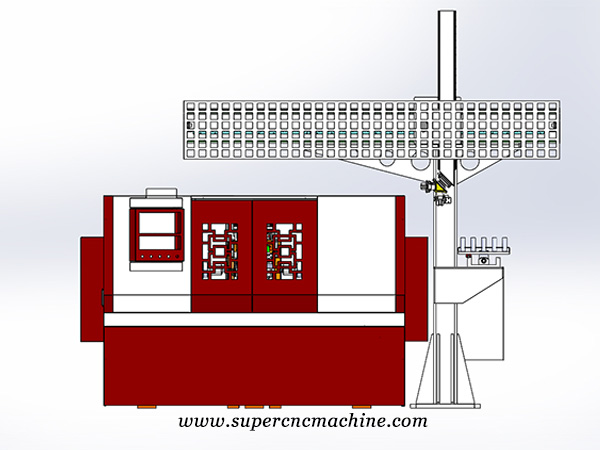

- CNC36S1 CNC Lathe e With Truss Feeding Mechanism

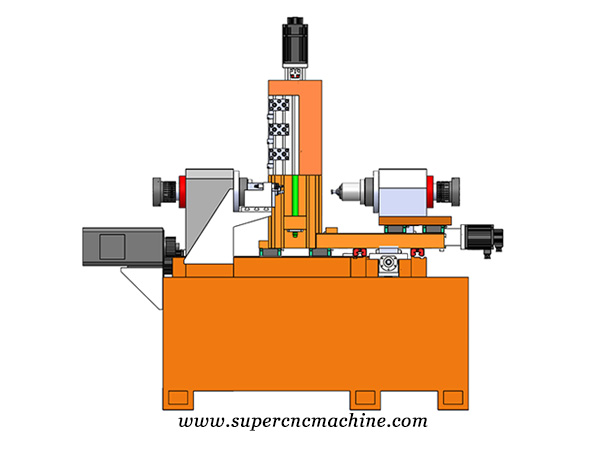

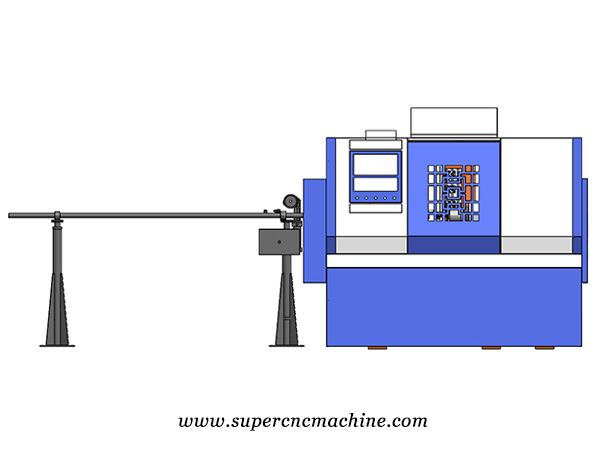

- CK42S2 CNC Lathe with pneumatic feeding mechanism

Fully Automatic Double Spindle CNC Lathe Parameters

| Model | CK35S1 | CK45S1 | CNC36S1 | CK42S2 | |

| 1 | Standard system | SYNTEC 21TB/KND 1000T | SYNTEC 21TB/KND 1000T | SYNTEC 21TB/KND 1000T | SYNTEC 21TB/KND 1000T |

| 2 | Max. turning diameter of the bed(mm) | φ400 | φ400 | φ450 | φ450 |

| 3 | Max. turning diameter of the pallet(mm) | φ160 | φ160 | φ160 | φ160 |

| 4 | X axis max. Stroke(mm) | 350 | 350 | 300 | X1:360 X2:360 |

| 5 | Z axis max. stroke(mm) | 250 | 250 | 200 | Z1:300 Z2:350 |

| 6 | Spindle | Spindle unit 150/electric spindle | Spindle unit 170/electric spindle | Electric spindle | Electric spindle |

| 7 | Spindle speed (rpm) | 50-2500(50-5000) | 50-2500(50-5000) | 50-5000(定制) | 50-5000 |

| 8 | Spindle hole diameter(mm) | φ45 | φ49 | φ46 | φ49 |

| 9 | Servo main motor power(KW) | 4/5.5 | 4/5.5 | 4/5.5/7.5 | 5.5 |

| 10 | X axis servo motor(N.m) | 6 | 6 | 6 | 6 |

| 11 | Z axis servo motor(N.m) | 4 | 4 | 8 | 8 |

| 12 | Clamping method | Hydraulic/pneumatic | Hydraulic/pneumatic | Hydraulic/pneumatic | Hydraulic/pneumatic |

| 13 | Tool holder form | Row tool | Row tool | Row tool | Row tool |

| 14 | Number of tools | 4 | 4 | 4 | 4 |

| 15 | Tool square size(mm) | 20×20 | 20×20 | 20×20 | 20×20 |

| 16 | Rail form(X/Z axis) | Linear guides | Linear guides | Linear guides | Linear guides |

| 17 | Bed form | Flat bed | Flat bed | Slant bed | Slant bed |

| 18 | Tailstock power | No | No | No | No |

| 19 | Min setting unit(mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| 20 | Min movement(mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| 21 | Min detection volume(mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| 22 | X axis rapid movement(m/min) | 18 | 18 | 18 | 18 |

| 23 | Z axis rapid movement(m/min) | 20 | 20 | 20 | 20 |

| 24 | Total machine weight(kg) | 2600 | 3400 | 3400 | 4500 |

| 25 | Dimensions

(L X W X H)(mm) |

2300X1700X1800 | 2850X1850X2000 | 2250X1880X2350 | 2600X1990X1880 |

| 26 | Main feature | higher cost performance | higher cost performance | Easy chip removal.

The self-gravity can eliminate the lead screw gap, and the accuracy is higher. |

The vertical and horizontal positions of the tool post are staggered, which saves the space of the machine tool while increasing the number of tools. It has the advantages of compact structure, multiple functions, high efficiency, and good cost performance, and is convenient for chip removal.

2. The self-gravity can eliminate the lead screw gap, and the accuracy is higher. 3. Since one spindle of the machine tool is fixed, both long and short blank materials can be processed automatically. |

Fully Automatic Double Spindle CNC Lathe Advantages

- High efficiency: short machining cycle, reducing non-cutting time; (the second spindle can realize complete synchronous turning, and can quickly transfer workpieces during the machining process through program control, so as to shorten the cycle time).

- High precision: Equipped with the second spindle and the second tool post to realize the rotating docking of the workpiece and secondary processing, which reduces the clamping time and improves the coaxiality of the machine tool;

- High space efficiency: the smaller space plays the biggest role, which is convenient for personnel operation and automatic loading and unloading;

- X/Z axis adopts three-point positioning ball screw, which is easy to install, improves the service life of the bearing, reduces the thermal error of the machine tool, has high positioning accuracy, good stability and easy maintenance;

- X/Z axis adopts linear guide rail design, which increases the higher dynamic and static load of the guide rail, improves the rigidity of the machine tool, has high positioning accuracy, good stability and easy maintenance;

- The spindle unit or electric spindle can be customized to ensure that the machine tool has better rigidity during fast operation;

- The machine tool adopts an integral casting bed with good stability. The bed can be clamped and processed at one time, with high precision and durability.

- Combine two independent machine tools into one, and use a numerical control system together, so that you can operate independently, or work together to complete the other half of the work, which can save the area of the machine tool, the operator, the handling time and the machine running time, and at the same time improve the accuracy of the product.

- CK35S1 & CK45S1 Double Spindle Flat Rail CNC Lathe

- CNC36S1 double-spindle double-inclined CNC lathe

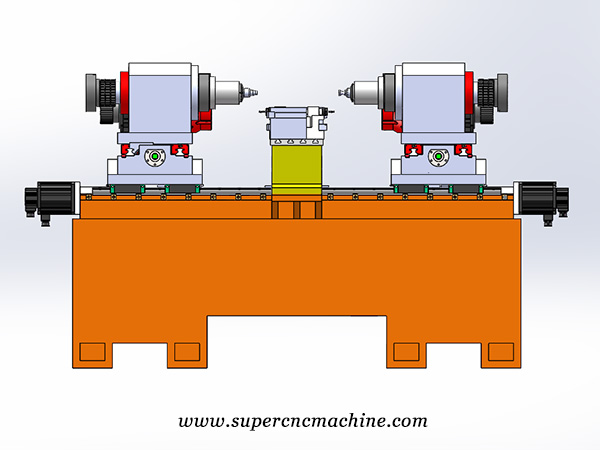

- CK42S2 double-spindle vertical rail CNC lathe

- Structure drawing of CK42S2 double-spindle vertical rail CNC lathe

About HAISHU Machinery

As the professional CNC machine designer and manufacturer, Taian HAISHU Machinery Co., Ltd (Haishu Machinery) is the high-tech enterprise specialized in CNC machine development, production, sales and service since 2001. We have more than 30 professional talented CNC experts and more than 12,000 square meters manufacturing factory. Our high quality and innovative products include CNC lathe, CNC milling machine, CNC machining center, CNC turn-mill machine, CNC tool grinding machine, CNC pipe threading lathe, CNC wood lathe, stone CNC machine, CNC root canal file grinder and custom CNC equipment for special requirements.

HAISHU Machinery is not only manufacturing best quality CNC machine products but also providing custom product design and after sale services. Welcome, contact us for detailed information.