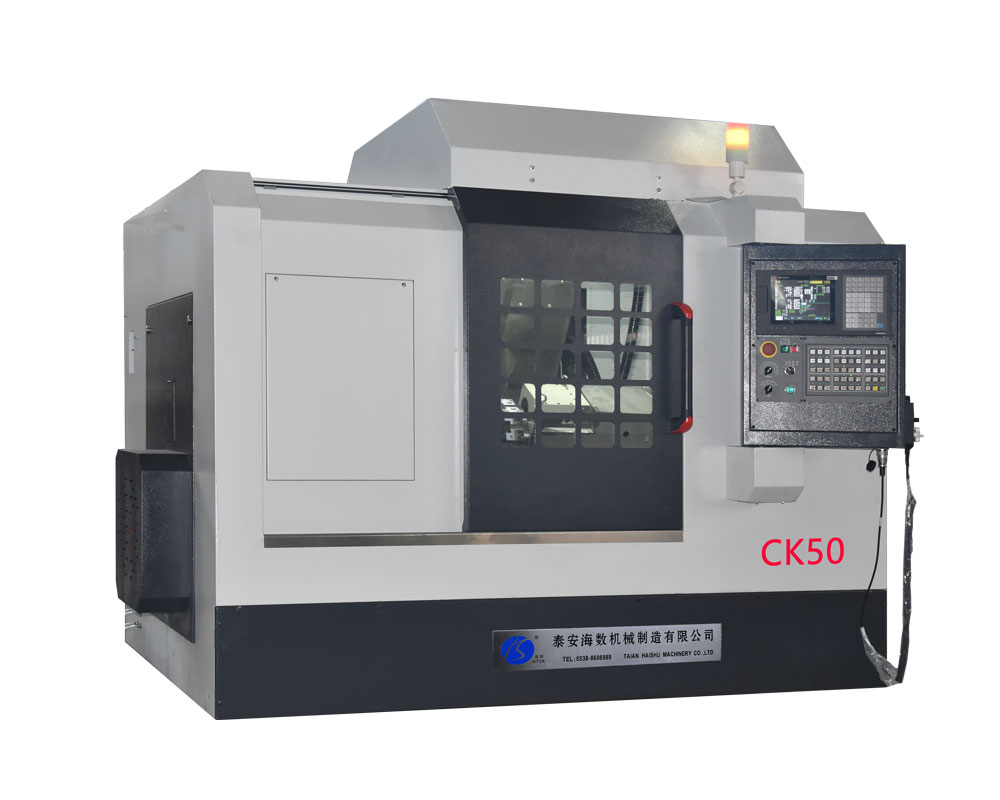

Advanced CNC Lathe is a high-precision and high-efficiency automatic machine tool. Equipped with a multi-station turret or power turret, the CNC machine tool has a wide range of technological performance and can process linear cylinders, oblique cylinders, circular arcs, and various threads, grooves, worms, and other complex workpieces. It has linear interpolation and arc interpolation and compensation functions. The advanced CNC lathe also has good economic effect in the mass production of complex parts.

The plane of the two guide rails of the CNC lathe machine intersects the ground plane and forms a slant plane with angles of 30°, 45°, 60°, and 75°. The bed of the CNC lathe is a right triangle. Obviously, in the case of the same guide rail width, the X-direction carriage of the slant bed is longer than the flatbed. The practical significance of the application on the lathe is that tool positions can be arranged. The cross-sectional area of the advanced CNC lathe is larger than that of the flatbed of the same specification, that is, the ability to resist bending and torsion is stronger.

Types Of Advanced CNC Lathe

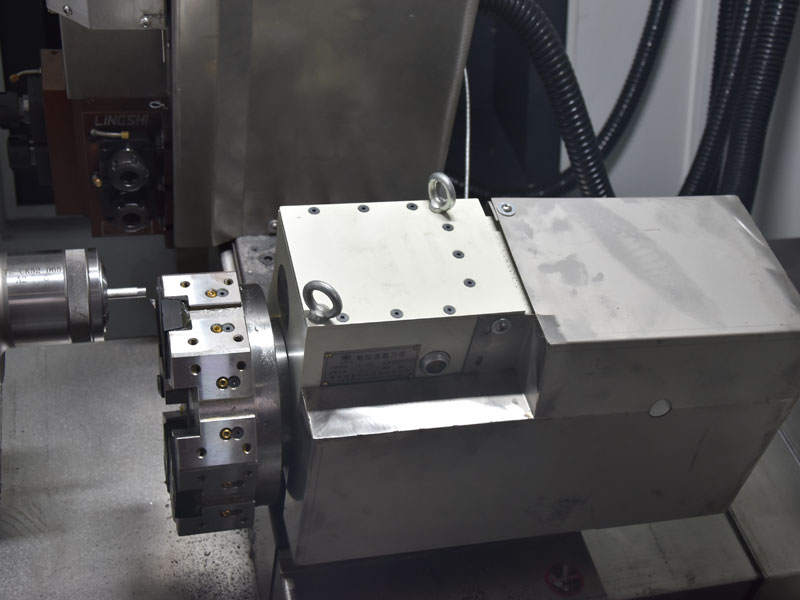

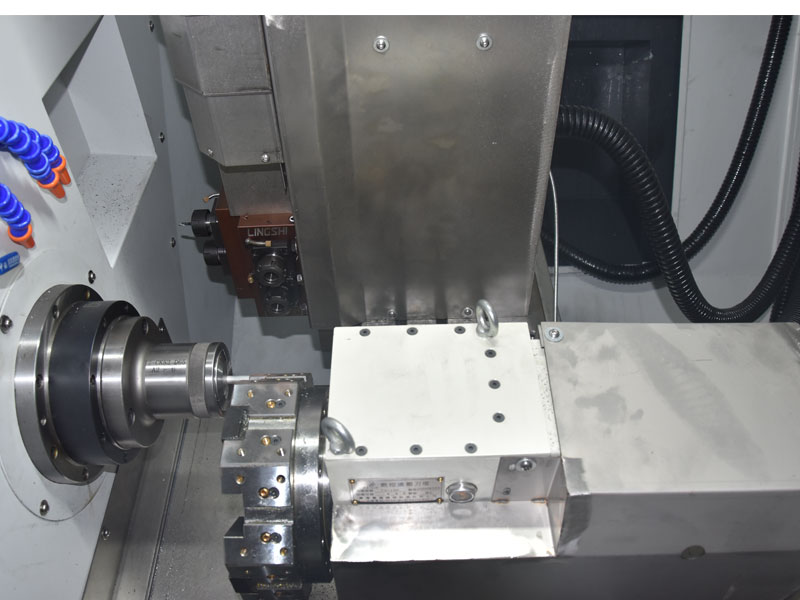

- The CNC lathe is composed of a CNC control system, a bed, a headstock, a tool post feed system, a tailstock, a hydraulic system, a cooling system, a lubrication system, and a chip conveyor.

- Parallel double spindle CNC lathe.

- Advanced CNC lathe is divided into two types: vertical CNC lathes and horizontal CNC lathes.

- Vertical CNC lathes are used for turning disk parts with larger turning diameters.

- Horizontal CNC lathes are used for turning processing of parts with long axial dimensions or small disks.

- Advanced CNC lathe can be further divided into economical CNC lathes, ordinary CNC lathes, and turning machining centers according to their functions.

- Economical CNC lathe: A simple CNC lathe formed by reforming the turning feed system of an ordinary lathe with a stepping motor and a single-chip computer. The cost is low, the degree of automation and functions are relatively poor, and the machining accuracy of turning is not high. It is suitable for turning machining of rotary parts with low requirements.

- Ordinary CNC lathe: a CNC lathe that is specially designed in structure according to the requirements of turning processing and is equipped with a general CNC system. The numerical control system has strong functions, high degree of automation and processing accuracy, and is suitable for turning processing of general rotary parts. This CNC lathe can control two coordinate axes at the same time, namely the x-axis and the z-axis.

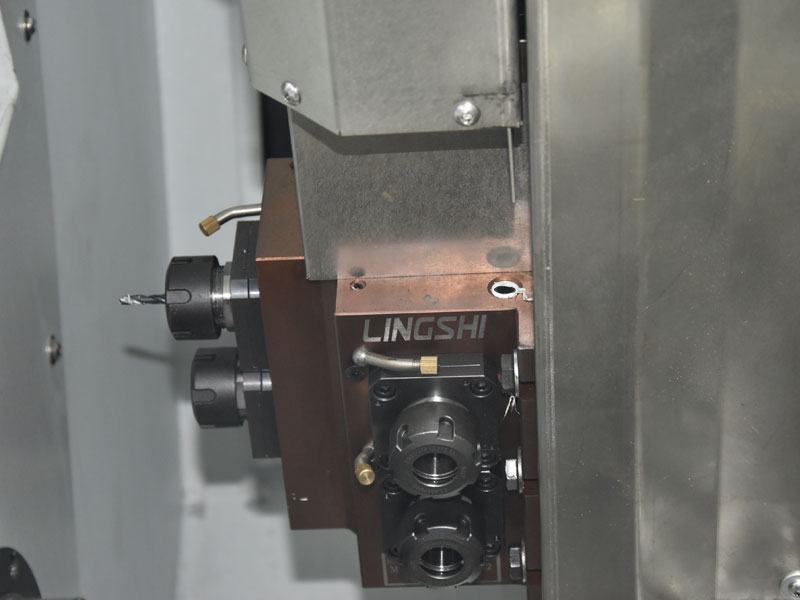

- Turning center

- Turning machining center: On the basis of ordinary CNC lathes, a C axis and power head are added. More advanced machine tools also have a tool magazine, which can control the three coordinate axes of X, Z and C. The linkage control axis can be (X, Z), (X, C) or (Z, C). Due to the addition of the C-axis and milling power head, the processing functions of this CNC lathe are greatly enhanced. In addition to general turning, it can also perform radial and axial milling, surface milling, and holes and diameters whose centerline is not at the center of the part’s rotation. Drilling and other processing of holes.

Advantages Of Advanced CNC Lathe

- The linear rolling guide of the CNC lathe meets the requirements of high-speed and high-efficiency, reduces frictional resistance and temperature rise deformation, improves machining accuracy, and can ensure the long-term stability of cutting machining accuracy.

- The tool detection device can automatically input the tool tip position data into the CNC system, which greatly reduces the settling time when changing the tool, and can also automatically compensate for the wear of the tool tip.

- CNC lathe adopts domestic or imported high-rigidity horizontal turret tool post, which has high positioning accuracy and small re-cutting deformation.

- Standard configuration: spindle stepless speed regulation, hydraulic chuck, hydraulic tailstock, horizontal eight-position tool post, enclosed protection.

- The CNC lathe adopts the overall slant bed structure, which can still maintain the stability of the machine tool accuracy when re-cutting.

- The X and Z axis servo motors are directly connected to the precision ball screw through the elastic coupling. The precision is high. The two ends of the screw are fixed, which improves the support rigidity of the support seat, so that the frequent high-speed positioning and the wire caused by re-cutting The distortion of the bars is minimized.

- High-precision, high-rigidity programmable tailstock.

- In the design of the CNC lathe, the spindle box has taken corresponding measures to reduce the thermal deformation of the spindle, so that the spindle can maintain the relative stability of the spindle axis during long-term operation.

- The CNC lathe adopts full guide rail protection, and the cooling box and chip conveyor are separated from the host to ensure the accuracy of the machine tool from thermal cutting.

- Good stability. The parts that need to be processed are generally slant bed or flatbed slant guide rail machine tools, because the corresponding parts of medium and large machine tools are also large, especially the turret part. The slant guide rail is mainly used to overcome gravity and have better stability to improve The accuracy of the machine tool can reflect the superiority of the slant machine tool in some harsh environments.

- Improve utilization. Slant machine tools can effectively use space and greatly reduce the floor space of the machine tools.

- Easy chip removal

The slant guide rail also facilitates the concentration of iron chips on the chip conveyor for automatic chip removal. The iron filings under cutting carry high heat, and the accumulation on the guide rail will cause the guide rail to be heated and deformed, which will change the working accuracy, and will cause batches of workpieces to be scrapped in the batch automatic processing process.

About HAISHU Machinery

HAISHU has the design, manufacture, sales, and maintenance capabilities of advanced CNC lathes. Our company has been established for eleven years and has trading partners in more than 90 countries and regions around the world. Our CNC lathe machine can provide you with a high-quality and high-efficiency metal processing experience, welcome to visit and guide the company.