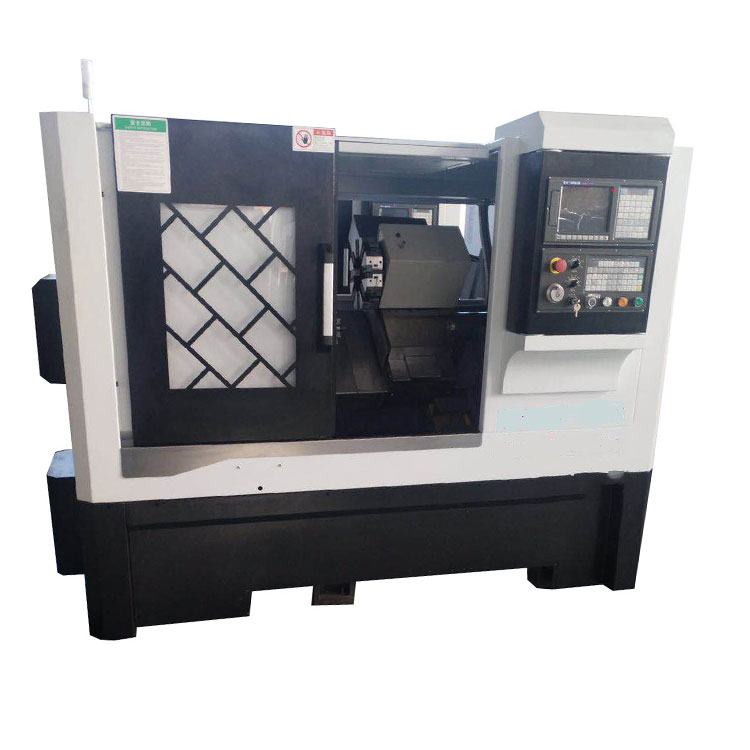

CNC Turning Lathes are the most widely used CNC machine tools. Haishu Brand CNC tuning lathe is mainly used for the inner and outer cylindrical surfaces of shaft parts or disc parts, the inner and outer conical surfaces of any taper angle, the complex inner and outer curved surfaces, the cylindrical and conical threads, etc., The CNC turning lathes can also be used for grooving, drilling, reaming, holes and borings, etc.

The CNC lathe automatically processes the machined parts according to the pre-programmed machining program. We process the machining process route, process parameters, tool trajectory, displacement, cutting parameters and auxiliary functions of the parts according to the instruction code and program format specified by the CNC machine tool, and then record the contents of the program list. On the control medium, it is then inputted into the numerical control device of the CNC machine to direct the machine to machine the parts.

CNC Turning Lathes Characteristics

CNC machine tool is the abbreviation of digital control machine tool, which is an automatic machine tool with a program control system. The control system can logically process and decode the program with a control code or other symbolic instructions to cause the machine to operate and machine the part.

Compared with ordinary machine tools, CNC machine tools have the following characteristics:

- High processing precision and stable processing quality;

- The multi-coordinate linkage can be performed to process parts with complex shapes;

- When the machining parts are changed, generally only the NC program needs to be changed, which can save production preparation time;

- The machine tool itself has high precision and rigidity, and can choose favorable processing amount and high productivity (usually 3~5 times of ordinary machine tools);

- The degree of automation of the machine tool is high, which can reduce the labor intensity;

- The quality of the operators is high, and the technical requirements for maintenance personnel are higher.

Selection principle

To determine the process requirements of typical parts and the batch size of the machined parts, it is necessary to prepare the functions of the CNC Turning Lathes in advance. The preconditions for the rational selection of CNC Turning Lathes are: meet the technical requirements of typical parts.

The process requirements for typical parts are primarily the structural dimensions, processing range and accuracy requirements of the part. According to the accuracy requirements, that is, the dimensional accuracy, positioning accuracy and surface roughness of the workpiece, the control precision of the CNC lathe are selected. According to the reliability, reliability is a guarantee to improve product quality and production efficiency. The reliability of a CNC machine tool means that the machine tool runs stable for a long time without failure when it performs its function under specified conditions. That is, the average time between failures is long, and even if a fault occurs, it can be recovered in a short time and put back into use. Choose machine tools that are well-structured, well-made, and mass-produced. In general, the more users, the higher the reliability of the CNC system.

Machine tool accessories and tools

Machine tool accessories, spare parts and their supply capacity, tools, are very important for the production of CNC Turning Lathes and turning centers. When choosing a machine tool, careful consideration must be given to the fit of the tool and accessories.

Manufacturers generally choose the same manufacturer’s products, at least should choose the same manufacturer’s control system, which brings great convenience to the maintenance work. Teaching units, because they need students to be knowledgeable, choose different systems, and equipped with various simulation software is a wise choice.

Performance price ratio to choose

Do the function, the precision is not idle, not waste, do not choose the function that has nothing to do with your needs.

Machine protection

When required, the machine can be equipped with fully enclosed or semi-closed guards and automatic chip evacuation.

When selecting CNC Turning Lathes and turning centers, the above principles should be considered comprehensively.

About HAISHU Machinery

Taian Haishu Machinery Co., Ltd. is the professional CNC machine designer and manufacturer dedicated to supplying automobile wheel production and repair solutions to worldwide customers. We have been always worked hard to become the leader in designing and manufacturing CNC Turning Lathes since 2001. We have more than 30 talented experts and more than 12,000 square meters factory. Our innovative, high-quality products include wheel CNC machine, wheel repair machine, brake drum lathe and customized CNC machine.